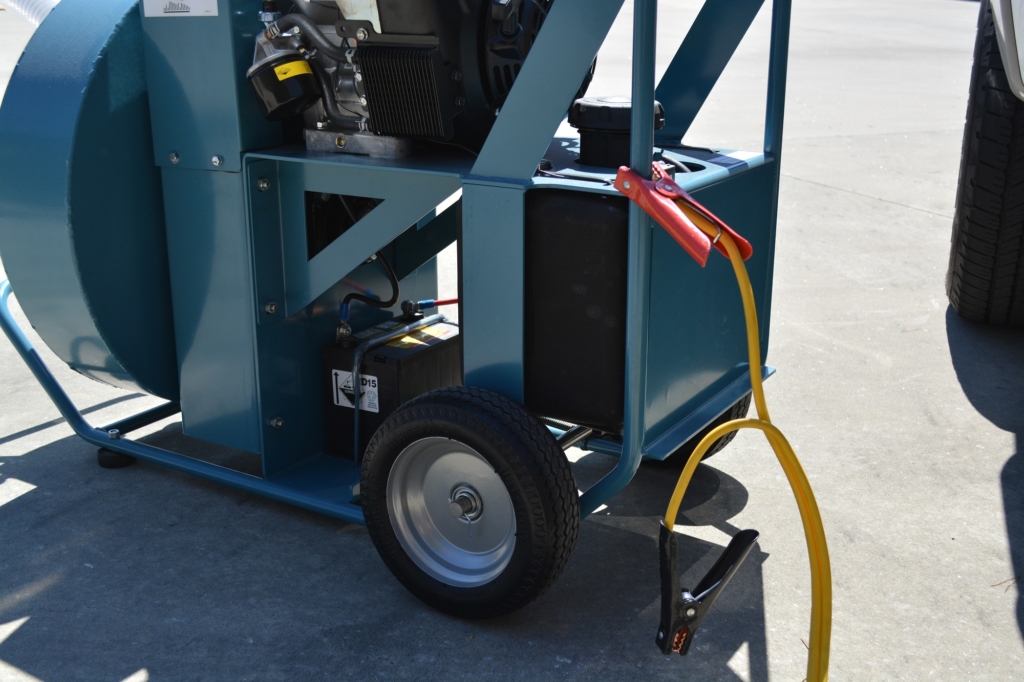

The friction of insulation in an insulation hose can occasionally cause a static charge to build that can shock the equipment operator. It is good practice to ground your machines.

For Insulation Blowing Machines

Occasionally, clients report that using the insulation blowing equipment during a routine attic capping or restoration job causes a static charge that can shock the equipment operator. The easiest way to avoid this is by grounding your equipment. In order to do so, take a standard pair of jumper cables and attach one end to a metal area on the equipment while the other end is attached to a metal bumper or trailer hitch of your truck or trailer. This will prevent static from building.

For Insulation Vacuums

Occasionally, clients report that using the vacuum equipment during a routine attic restoration job causes a static charge that can shock the equipment operator. The easiest way to avoid this is by grounding your equipment. In order to do so, take a standard pair of jumper cables and attach one end to a metal area on the vacuum while the other end is attached to a metal bumper or trailer hitch of your truck or trailer. This will prevent static from building.

Another solution is the new Anti-Static Vacuum (ASV) Wand, which, when used with the Krendl GV230XL or GV180 vacuum systems, reduces the opportunity for static charges to build.